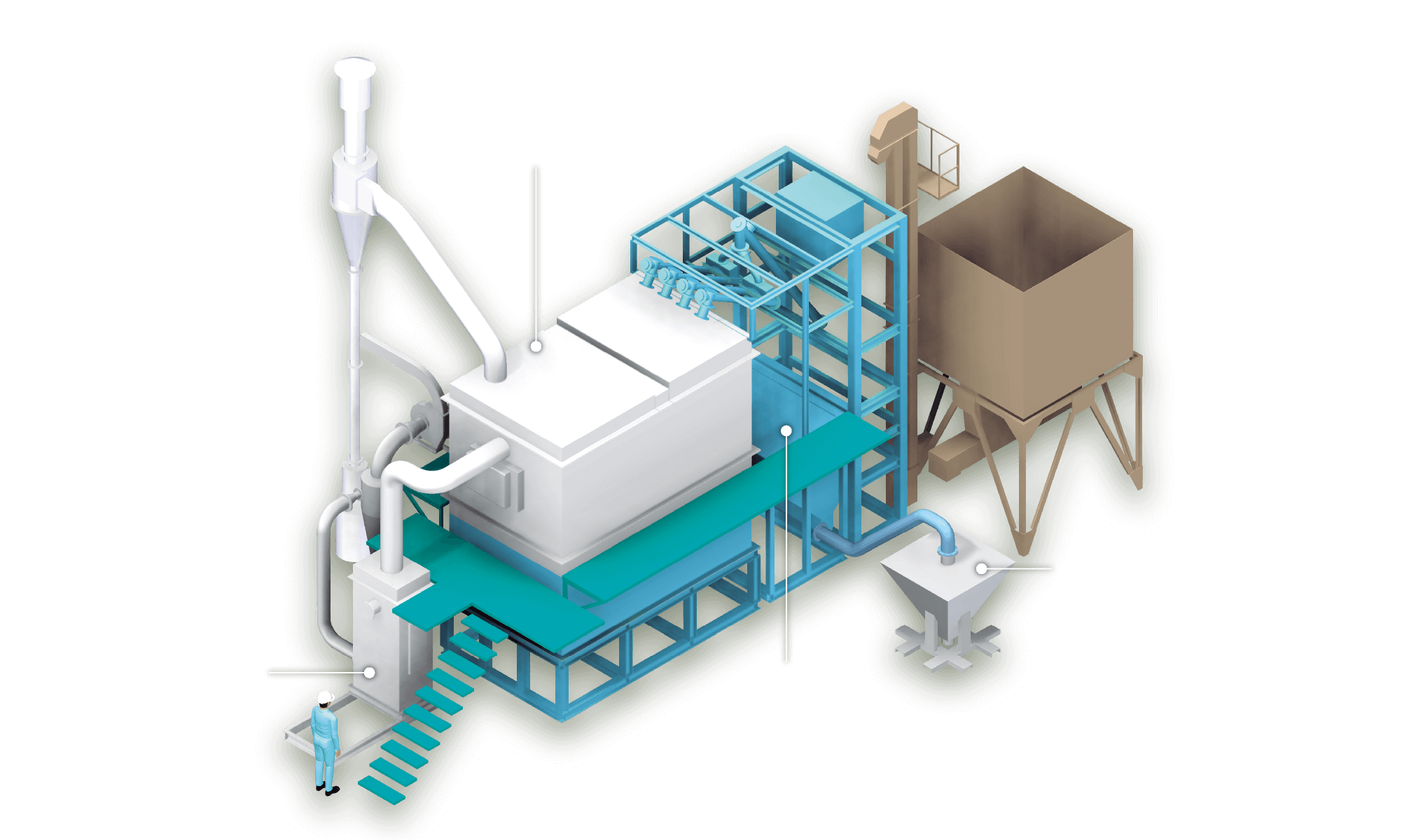

Rice husk processing furnace

Complete recycling of rice husks

"Environmental Furnace Series Rice Husk Processing Furnace" heat-treats industrial waste "rice husk" with advanced control technology to produce "rice husk ash" containing beneficial amorphous soluble silica without emitting harmful substances. is a facility that manufactures

New technology enabling safe extraction of amorphous and soluble silica

Rice husk contains about 20%Silica (SiO2 silicic acid)However, at normal processing temperature (1,000°C), silica crystallizes and does not dissolve in water. For this reason, although silica is necessary for the growth of rice plants, even if the ash after burning is returned to the paddy fields, the rice plants cannot absorb it, and in the end, the rice husks and rice husk ash become waste.

At NSIC, as a member of the "Rice Husk Recycling Project Team," we have been working on heat-treating rice husks to convert them into energy and turning the ash into silica. In order to utilize the silica contained in rice husks, it is essential that it be amorphous and soluble.

For these issues, the project teamFurnace controlestablished a new technology for the production of energy and high-purity amorphous rice husk silica ash. As a result, it has become possible to manufacture "rice husk silica ash" according to its uses, such as agriculture, industry, and food additives. Since it can be produced only by constant temperature stable combustion technology, silica can be extracted at low cost. It is safe because it is non-crystallized silica derived from rice husks.

Condition of rice husk silica ash

| amorphous | no peak Analysis method: X-ray diffraction |

|---|---|

| soluble | 60% or more Analysis method: Potassium fluoride method |

| Highly active | 2.0-3.0 Analysis method: Luxan method |

| fixed carbon | 15% or less Analysis method: mass calculation |

Composition table of rice husk silica ash

Other components: K2O, CaO, MgO, etc.

Various types of rice husk processing furnaces

| Model | processing power (continue) | Approximate dimensions (furnace + holding chamber) | hot water boiler heat exchange |

|---|---|---|---|

| MTP-200 | 120kg/hr | 6,500L×2,800W×5,500H | Approx.142kW |

| MTP-100 | 80kg/hr | 5,900L×2,100W×5,100H | - |